| Buy Together scott volumeter – air jet test sieve shaker – particle size analyzer price – fisher sub sieve sizer – tablet friability tester | |

| Overview | Specifications | Principle | Features | Demo Video | Applications | FAQs | Price | Similar Products | |

| (Last Update: Feb 2, 20195) | |

| Overview | |

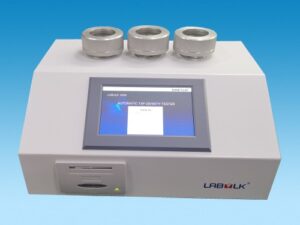

| Tapped Density Tester, also named Tapped Density Analyzer or Tapped Density Meter . AS-100 Tapped Density Tester is a density measurement equipment used to measure the tapped density of powders, as well as granulated or flaked materials by standardized and repeatable procedures. AimSizer offers simple-design tap density tester and tap density testers integrated with printer such as one-station tapped density tester and two-station tapped density tester. AS-100 tap density testers meet all international standards on cost-effective basis.

Applications in pharmaceutical (Compressibility Index/Carr’s Index and Hausner Ratio) |

|

| In addition, AS-100 Tapped Density Tester meets international standards such as – ASTM D 4164 Standard Test Method for Mechanically Tapped Packing Density of Formed Catalyst and Catalyst Carriers – ASTM D 4781 Standard Test Method for Mechanically Tapped Packing Density of Fine Catalyst Particles and Catalyst Carrier Particles – ISO 8460 Instant coffee — Determination of free-flow and compacted bulk densities – ISO 8967 Dried milk and dried milk products — Determination of bulk density – ISO 9161 Uranium dioxide powder — Determination of apparent density and tap density |

|

|

|

|

as-100-tap-density-tester-price-manufacturers-two-stations-with-printer

|

|

|

|

|

as-100-tapped-density-testers-price-manufacturers-single-platform

|

|

|

|

|

as-100-tap-density-tester-simple-design-without-printer-1-station-price-manufacturer

|

|

|

|

|

as-100-tap-density-tester-with-acoustic-cabinet

|

|

| • AS-100 Tap Density Tester Specifications | |

| • AS-100 Tap Density Tester Working Principle | |

| • AS-100 Tap Density Tester Features | |

| • AS-100 Tap Density Tester Applications | |

| • What Is Tap Density? | |

| • What Is Bulk Density Divided Into? | |

| • What Does TAP Mean In a Tap Density Tester? | |

| • How to Measure Tapped Density? | |

| More Pictures | |

| Demo Video | |

| Tapped Density Tester | |

| How to use An AS-100 Tap Density Tester | |

| Press timer right arrow to adjust the time to be used. Press the up arrow to decide. The maximum time to set is 99min 59sec. In case everything is OK, press the square button to start tapping. In practice, it is possible to determine the minimum tap number N when powder volume does not change anymore. For powders of the same kind, except for special tap number obtained during experiments (not less than N), tap them for 2N times. For metal powders in different size tapping 3000 times can achieve satisfactory results.Vibration frequency adjustment. User can turn the knob to select the appropriate frequency. The maximum is 300 rpm. Usually it is 100-300rpm. | |

| The amplitude of simple design is 3 mm, and frequency 300 tap/min. The tapping number is determined by time multiplying 300/min. The time is set by the timer.We usually set 10 minutes. The maximum working time is 99 minutes 59 seconds. When timer starts to work, the tap density starts to work as well. Please set the timer as follows:press Right Arrow once,panel starts flashing, press Up Arrow to set desired data. Hold until the panel stops flashing, press Square to start working. The tap density tester stops when the time runs out. User can also stop the operation any time by swiching off the machine. | |

|

|

|

| Reason: VOL “ 0 ”;Solution: Reset VOL | |

|

|

|

| Reason: WT “ 0 ”;Solution: Reset WT | |

|

|

|

| Reason: WT or VOL “ 0 ”;Solution: Reset WT and VOL | |

|

|

|

| Reason: Out of printing paper;Solution: Install new printing paper | |

|

|

|

| Reason: Thermo paper installed in wrong direction or bad paper quality ;Solution: Check the paper or replace | |

|

|

|

| Reason1:Forget to turn on speed adjuster. Solution1: Turn on speed adjuster.Reason2:Set low speed;Solution2: Turn the knob clockwise.Reason3: Tap finishes or TAP NUM “0”;Solution3: T Reset tap number. | |

|

|

|

| Reason:Linear bearing lack lubricant;Solution: Add some lubricant | |

|

|

|

| Reason1:Forget to turn on AS-100 Tap Density Tester;Solution1: Turn on unit. Reason2:fuse was burnt out.Solution2: Use new fuse | |

|

|

|

| After calculating and display, press the “PRINT” when green indicator light is on. | |

|

|

|

| After above step, press “CAL”, the computer completed density calculation based on ρ = m / v, and display the results. | |

|

|

|

| If the powder surface is level, read it directly. If not, read both max and min and use averaged results. Keep an estimated value. Press the “VOL” and input volume number. | |

|

|

|

| Press the “TAP NUM”, enter tap number. Press the “START” until the set number is completed, and instrument stops automatically. In practice, it is possible to determine the minimum tap number N when powder volume does not change anymore. For powders of the same kind, except for special tap number obtained during experiments (not less than N), tap them for 2N times. For metal powders in different size tapping 3000 times can achieve satisfactory results.Vibration frequency adjustment. User can turn the knob to select the appropriate frequency. The maximum is 300 rpm. Usually it is 100-300rpm. | |

|

|

|

| Add all sample into the cylinder, keep powder surface level. Place cylinder assembly into the vibration platform. | |

|

|

|

| Weigh an appropriate amount of the sample. Turn on AS-100, press “ WT ” , input numbers, and Max 5 digits. | |

|

|

|

| Typically, the powder is testable in its actual state. In some cases, user has to dry powder. If the powder is easily oxidized, dry it in a vacuum or inert gas. If the powder contains a volatile substance, do not dry. If it is not possible to be dried, test it in its actual state. | |

|

|

|

| Use tube brush to clean the inside of cylinder, or flush it with solvent such as acetone. If you use a solvent, it should be thoroughly dried before test. | |

|

|

|

| AS-100 uses thermal paper width 57.5 ± 0.5mm. Printing paper is installed when export. The green LED becomes flashing when the paper runs out. Turn off the unit, and then press the round button to open paper cabinet, remove the paper tube and load the new paper. Make the thermal side facing up. Close the door, and pull the paper end out from the slot. Turn on the unit, the green light stop flashing. Press the green LED (green LED also works as a key), a section of printing paper moves forward. When the unit is turned off, press the green button, at the same time turn on the unit then leave the green LED, it prints self-check slip. | |

|

|

|

| The maximum amplitude is 15mm and the default is 3mm (made up of 1 pc 1mm and 1 pc 2mm tapping washer). More tapping washer are available (1mm, 2mm or 5mm). Amplitude = Total height of tapping washer |

|

|

tap-density-tester-tapping-height-control

|

|

|

|

|

| –Place Polyurethane washer from the upper side of the cylinder.–Place screw cap from the upper side of cylinder.

–Place silica jel pad on bottom of the cylinder, –Screw down the cap slowly until get fixed. –Place the tapping apparatus into the hole in the guide bearing. Note: The cylinder is fragile, please handle carefully. |

|

|

tap-density-tester-tapping-assembly

|

|

|

|

|

| Save “TAP NUM,” “WT”, “VOL”, “No.” Operator needn’t input again when he test again if he does not change anything. Re-test samples, such as some of the data has not changed, the need to re-enter the data. “No.” is automatically increased by 1 after each calculation. | |

|

|

|

| Print test report | |

|

|

|

| Calculate on data obtained | |

|

|

|

| Restore the system to boot state, all data is restored to the status before pressing OK | |

|

|

|

| Remove the last bit of data just entered. | |

|

|

|

| Stop tapping before obtaining a result. Test report only shows the actual tap numbers. In the absence of re-setting “TAP NUM”, press “START” button, the system continues the remaining tap. | |

|

|

|

| Start test | |

|

|

|

| Test result | |

|

|

|

| Tap number of the test | |

|

|

|

| Volume of the powder | |

|

|

|

| Weight of the powder | |

|

|

|

| Reference number of the test | |

| Frequently Asked Questions | |

| • What are the features of accoustic cabinet for AS-100 tap density tester? | |

| • In what units tapped density report? | |

| • Measures of Compressibilty Index/Hausner Ratio | |

| • How to determine the apparent volume by a Tap Density Tester? | |

| • How is the bulk density of a powder determined? | |

| • What affect the bulk density? | |

| Why how the determination is made is essential accroding to USP 616 Bulk Density and Tapped Density of Powders using a tap density tester? | |

| -The bulk density of a powder is often very difficult to measure with good reproducibility and ,in reporting the results,it is essential to specify how the determination was made. | |

| How to express the bulk density according to international standard USP 616 Bulk Density and Tapped Density of Powders? | |

| -The bulk density is expressed in grams per mL although the international unit is kilograms per cubic meter because the measurements are made using cylinders.It may also be expressed in grams per cubic centimeter. | |

| What the bulk density depends on according to USP 616 Bulk Density and Tapped Density of Powders? | |

| -The bulk density depends on both the density of powder particles and the spatial arrangement of particles in the powder bed. | |

| What is the definiton of a bulk density according to USP 616 Bulk Density and Tapped Density of Powders? | |

| -The bulk density of a powder is the ratio of the mass of an untapped powder sample and its volume including the contribution of the interparticulate void volume. | |

| What are relation between USP 616 Bulk Density and Tapped Density of Powders and European Pharmacopoeia and Japanese Pharmacopoeia? | |

| -USP 616 Bulk Density and Tapped Density of Powders has been harmonized with the corresponding texts of the European Pharmacopoeia and /or the Japanese Pharmacopoeia. The portion that is not harmonized is marked with symbols to specifiy this face. | |

| What is test method 2 of international standard USP 616 Bulk Density and Tapped Density of Powders using a tap density tester? | |

| -The method 2 is approximately same as method 1, operator proceeds as directed under Method I except that the mechanical tester provides a fixed drop of 3+-0.2 at a norminal rate of 250 taps per minute. | |

| How to do if it is not possible to use a 100 g test sample during tap density testing using a tap density tester according to USP 616 Bulk Density and Tapped Density of Powders? | |

| -Generally,replicate determination are desireable for the determination of this property. Specify the drop height with the results.If it is not possible to use a 100 g test sample, use a reduced amount and a suitable 100ml graduated cylinder (readable to 1ml) weighing 130+-16g and mounted on a holder weighing 240+-12g. The modified test conditions are specified in the expression of the results. | |

| What is the test procedure in USP 616 Bullk Density and Tapped Density of Powders method 1 using a tap density tester? | |

| -Proceed as described in USP 616 for the determination of the bulk volume.Secure the cylinder in the holder. Carry out 10,500, and 1250 taps on the same powder sample and read the corresponding volumes V10,V500 and V1250 to the nearest graduated unit. If the difference between V500 and V1250 is less than or equal to 2ml,V1250 is the tapped volume.If the difference between V500 and V1250 exceeds 2ml,repeat in increments such as 1250 taps,until the difference between succeeding measurements is less than or equal to 2ml.Fewer taps may be appropriate for some powders, when validated. Calculate the tapped density using the relevant formula in USP 616 to calculate the final tapped volume and therefore calculate the final tapped density. | |

| What are major apparatus in usp chapter method 1 Bulk Density and Tapped Density of Powders using a tap density tester? | |

| -The major apparatus consists of the following:1.a 250ml graduated cylinder (readable to 2ml with a mass of 220+-44g 2.a settling apparatus capable of production, in 1 min, either nominally 250+- 15 taps from a height of 3+-0.2mm, or nominally 300+-15 taps from a height of 14+-2mm.The support for the graduated cylinder,with its holder, has a mass of 450 +- 10g. | |

| Similar Products | |

| ● AS-6393 Powder Tester | Pharmaceutical, Carr Index |

| ● AS-100 Tap Density Tester | Tapped density |

| ● AS-200 Scott Volumeter | Apparent density |

| Metallic powder, hall flowrate, apparent density | |

| ● AS-601 Apparent Density Tester | Plastic, apparent density, ISO 60 |

| ● AS-602 Apparent Density Tester | Plastic, apparent density, ASTM D1895 Test Method B |

| ● AS-603 Apparent Density Tester | Plastic, apparent density, ASTM D1895 Test Method A |

| ● AS-604 Pharmaceutical Plastics Pourability Tester | Pharmaceutical flowability and plastic pourability |